Applications

Inverters/UPS

In many applications UPS play a mission critical role where loss of power is not an option. Current and voltage sensor play a key role in controlling output current accurately to ensure efficiency and managing charging and discharging cycles to ensure long battery life.Lighting

Lighting control systems reduce energy usage and cost by helping to provide light only when and where it is needed. Lighting control systems typically incorporate the use of time schedules, occupancy control, and photocell control.Motor protection/monitoring

Motor protection and monitoring is essential for all industrial installations to work properly with adequate safety for machines and equipment. Protection of motors, generators are essential to ensure continuity, reliability and availability of service for industrial process facilities, data centers, hospitals etc.AC/DC drive

In todays world, wherever there is motion there is likely to be an electric drive. From elevators, conveyors, forklifts, pumps and a variety of motorised process equipment drives are critical for smooth operations and energy saving.Welding Machines

Current sensors are used in welding applications to provide a current proportional to the output signal to the PWM driver and feed back control loop. Electrohms current sensors are highly reliable and accurate,foruse power supplies for welding equipment.Energy management

Energy management is the proactive, organized and systematic coordination of procurement, conversion, distribution and use of energy to meet the requirements, taking into account environmental and economic objectives.Battery energy management

Battery health management predict the end-of-discharge (EOD) event that indicates that the battery pack has run out of charge for any given flight of an electric UAV platform. The amount of usable charge of a battery for a given discharge profile is not only dependent on the starting state-of-charge (SOC), but also other factors like battery health and the discharge or load profile imposed.Automation Devices

For better technology Automation devices are leading head, The Series of current sensors consists of both current switches and current transducers can be used to activate an external contactor. They can sense external currents with a Solid or Split current sensing ring.Featured Product

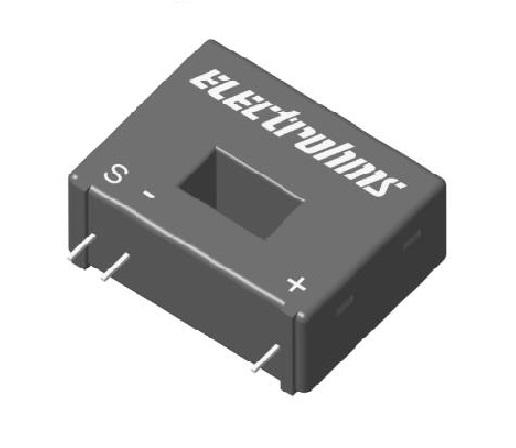

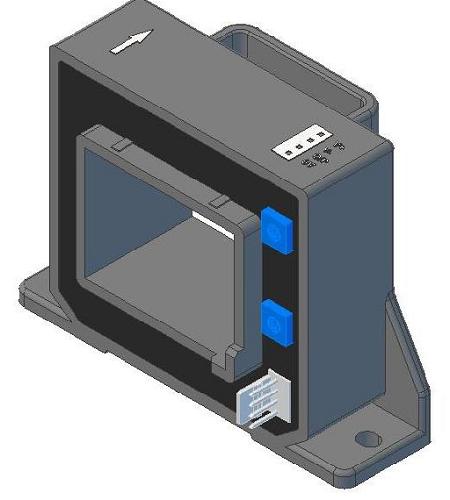

Closed loop hall effect current sensors are used in measurement of Alternating and Direct Current in electrical and electronic equipments such as SMPS, UPS, AC & DC industrial drives.

Resources

Closed loop hall effect current sensors are used in the measurement of Alternating and Direct Current in electrical and electronic equipments such as SMPS, UPS, AC & DC industrial drives, in process control applications like light control, heater load control, etc.

Resources

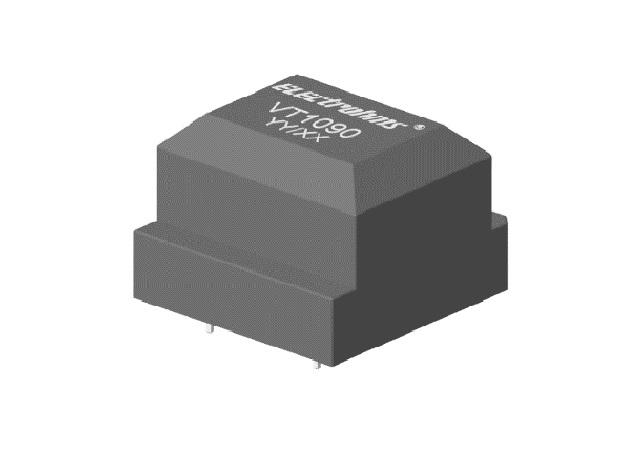

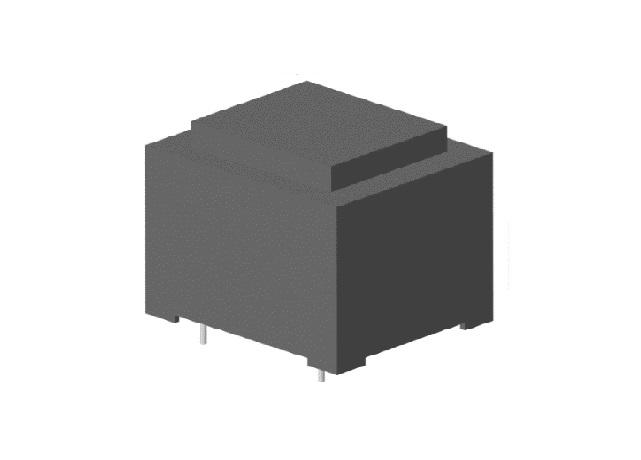

Voltage transformers (VT), also called potential transformers (PT), are used for metering and are designed to present negligible load to the supply being measured . They have an accurate voltage ratio to enable accurate metering.

Resources

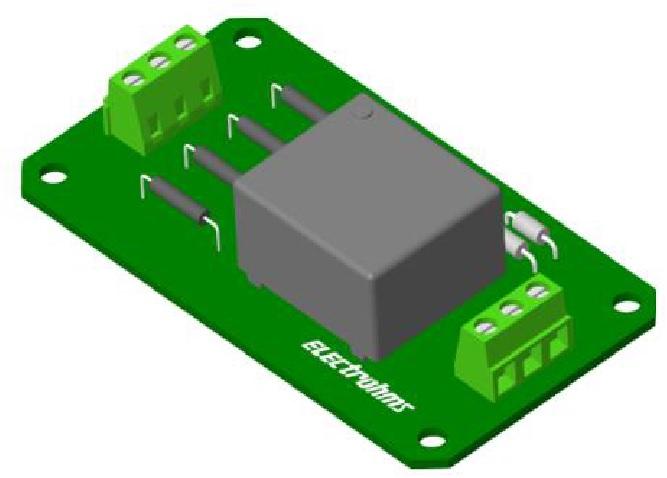

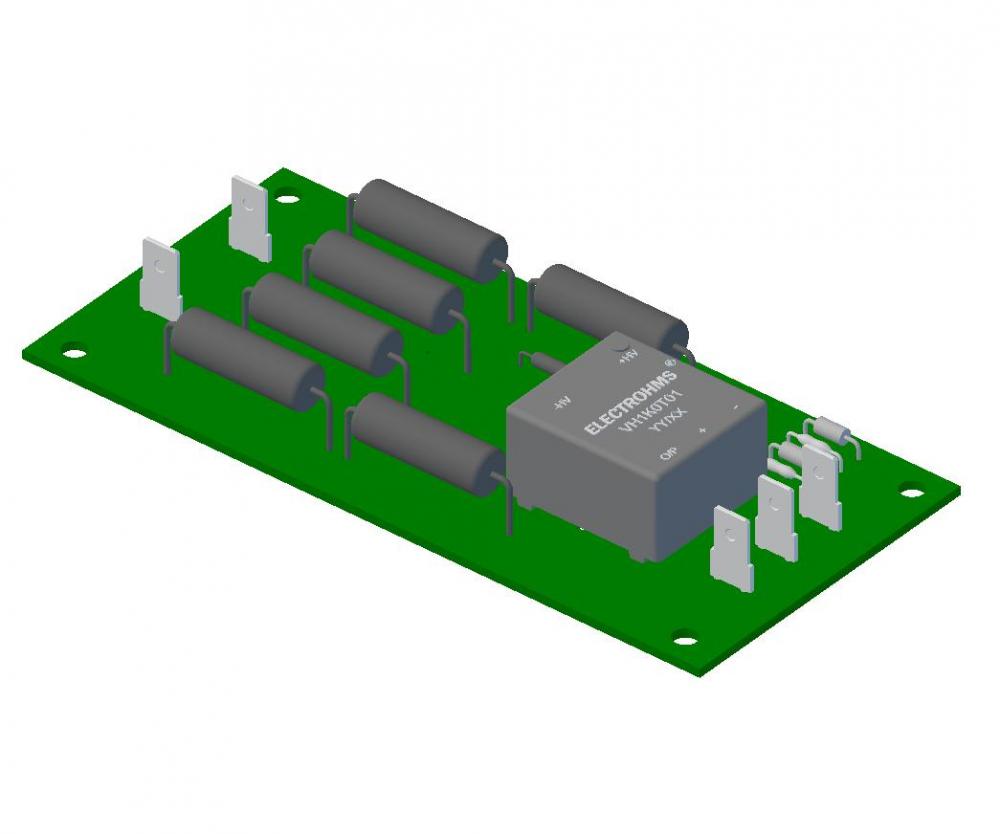

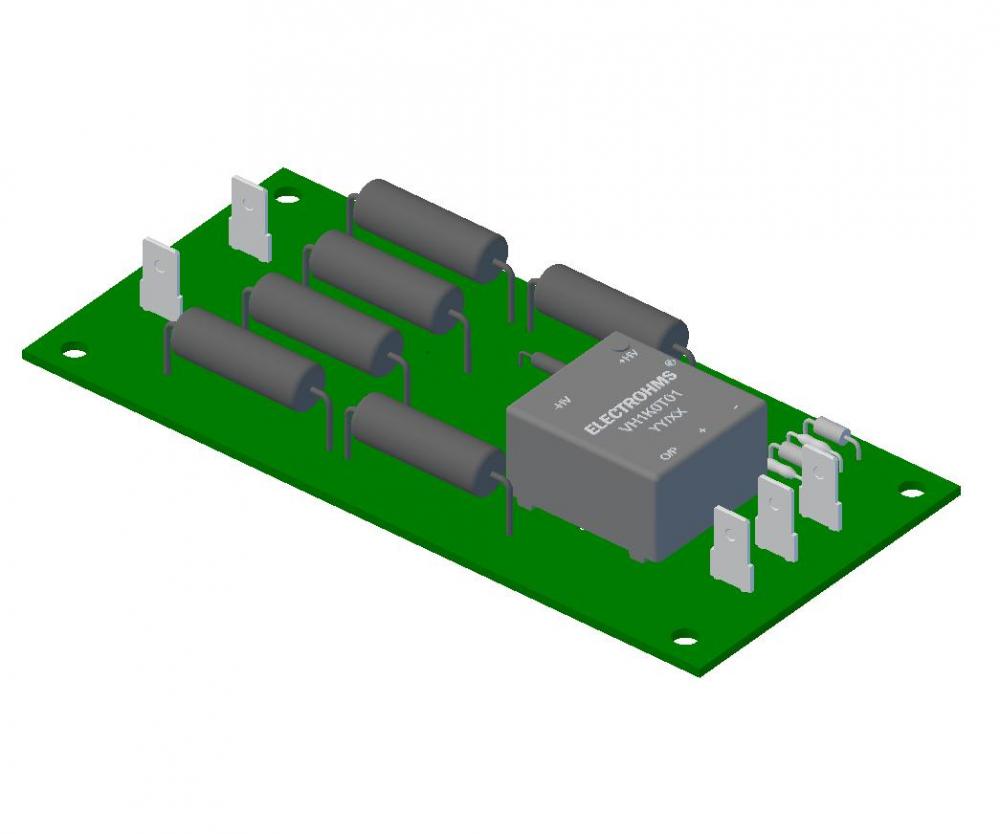

An integrated primary resistor networks determines the

nominal measuring voltage of the sensor. The advantages of VHASM150T01 is compact design, excellent accuracy (offset, sensitivity, linearity), low temperature drift.

Resources

An integrated primary resistor networks determines the nominal measuring voltage of the sensor. The advantages of VHASM500T02 is Compact design, Excellent accuracy (offset, sensitivity, linearity), Good response time, Low temperature drift.

Resources

An integrated primary resistor networks determines the nominal measuring voltage. The advantages of VHASM1K2T02 is Compact design, Excellent accuracy (offset, sensitivity, linearity), Good response time, Low temperature drift

Resources

VHASM1K0T01-CB11 - An integrated primary resistor networks determines the nominal measuring voltage of the sensor. It is available with wide selection of nominal voltage levels to cover a variety of applications.

Resources

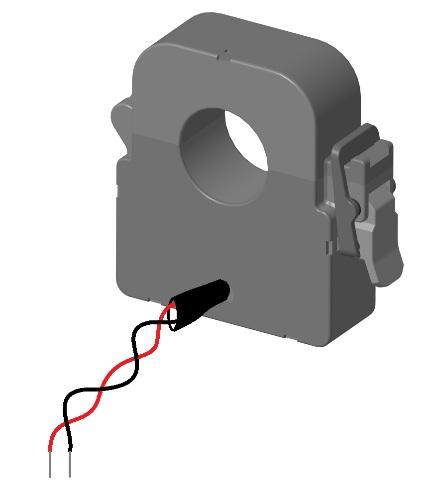

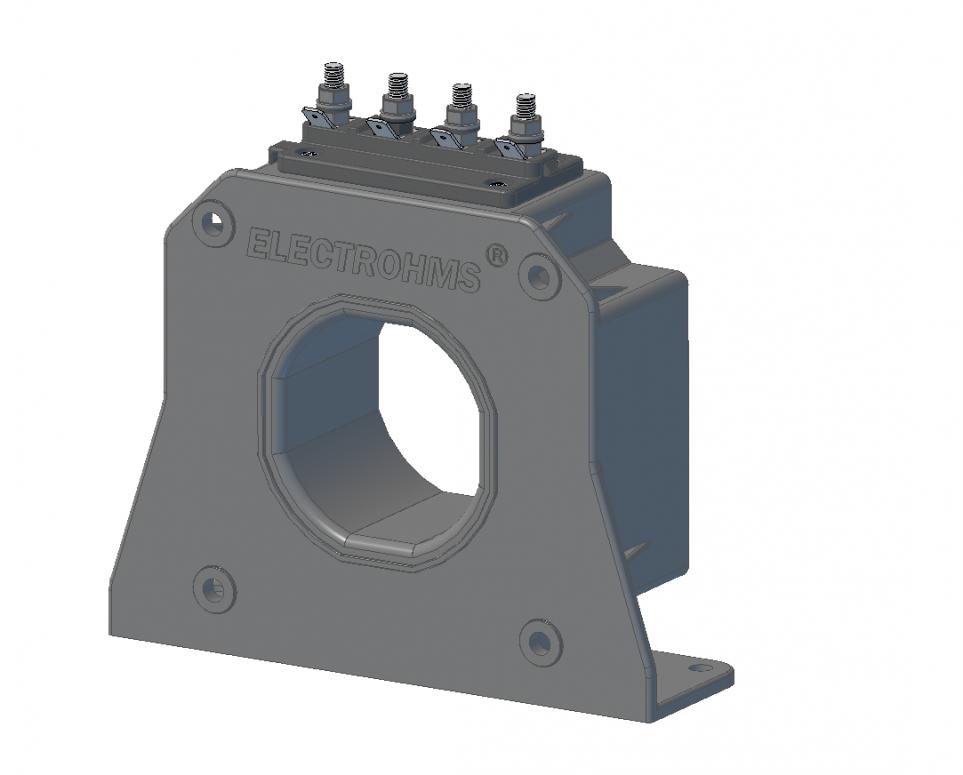

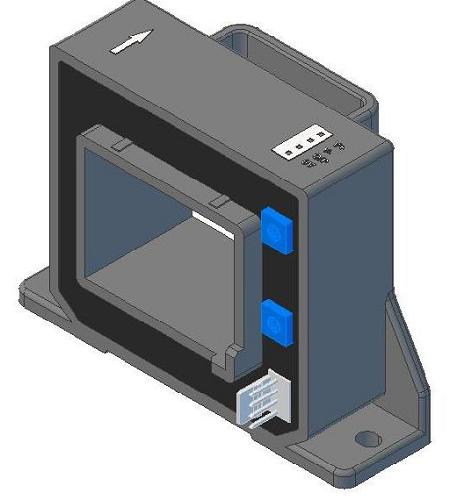

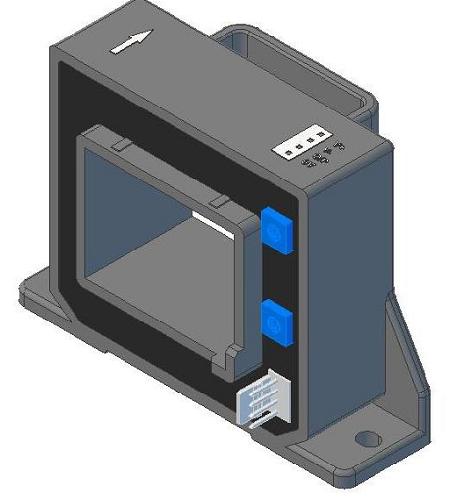

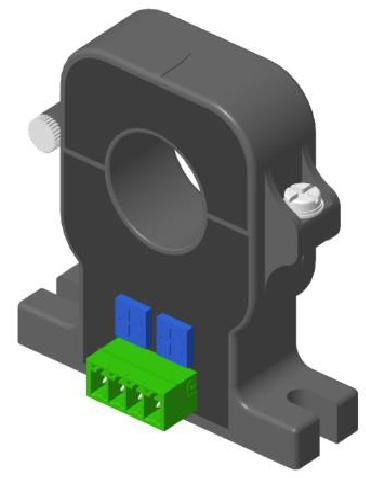

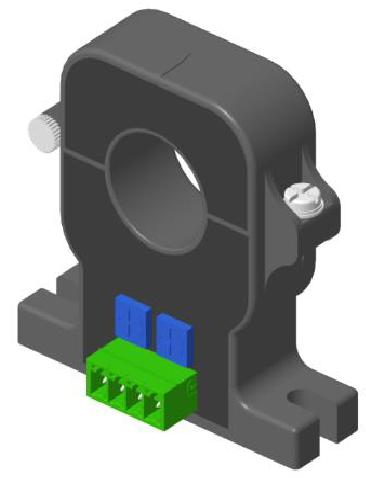

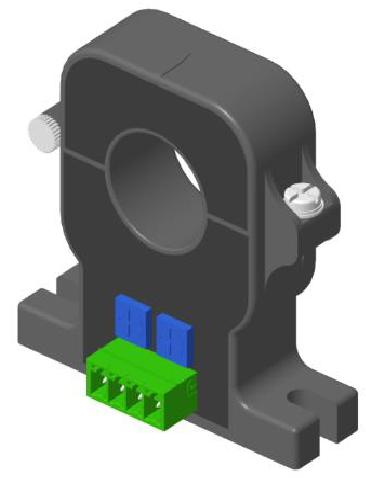

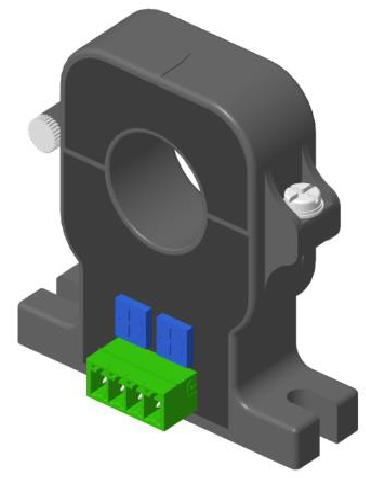

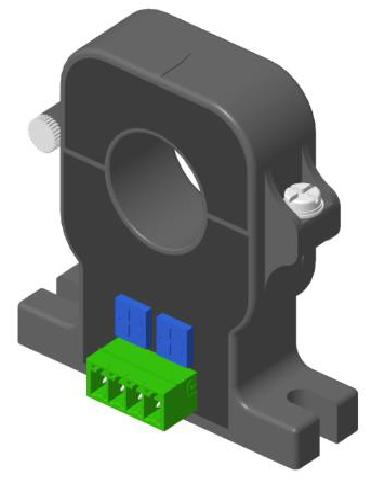

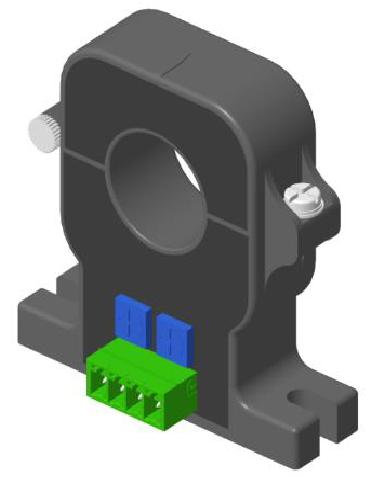

Split-core Hall Effect Current Sensor are perfect for clamping on existing electrical wiring by snapping around the current carrying cable. These are the best solution to measure or sense DC current passing through the center conductor, when the removal of cable lugs or termination is not feasible on critical installations.

Resources

Open loop hall effect current sensor measure DC, AC and complex current wave forms with galvanic isolation. The advantages include low cost, small size, lightweight and low power consumption and are especially advantageous when measuring high currents.

Resources

Open loop hall effect current sensor measure DC, AC and complex current wave forms with galvanic isolation. The advantages include low cost, small size, lightweight and low power consumption and are especially advantageous when measuring high currents.

Resources

Open loop hall effect current sensor measure DC, AC and complex current wave forms with galvanic isolation. The advantages include low cost, small size, lightweight and low power consumption and are especially advantageous when measuring high currents.

Resources

Open loop hall effect current sensor measure DC, AC and complex current wave forms with galvanic isolation. The advantages include low cost, small size, lightweight and low power consumption and are especially advantageous when measuring high currents.

Resources

The Rogowski coil is used for the current measurement of AC currents. This sensor can be clamped on to the existing cable without interruption of the primary circuit.

Resources

Split-core Hall Effect Current Sensor are perfect for clamping on existing electrical wiring by snapping around the current carrying cable. These are the best solution to measure or sense current passing through the center conductor, when the removal of cable lugs or termination is not feasible on critical installations.

Resources

Split-core Hall Effect Current Sensor are perfect for clamping on existing electrical wiring by snapping around the current carrying cable. These are the best solution to measure or sense current passing through the center conductor, when the removal of cable lugs or termination is not feasible on critical installations.

Resources

Split-core Hall Effect Current Sensor are perfect for clamping on existing electrical wiring by snapping around the current carrying cable. These are the best solution to measure or sense current passing through the center conductor, when the removal of cable lugs or termination is not feasible on critical installations.

Resources

Split-core hall effect current sensor are perfect for clamping on existing electrical wiring by snapping around the current carrying cable. These are the best solution to measure or sense current passing through the center conductor, when the removal of cable lugs or termination is not feasible on critical installations.

Resources

Split-core hall effect current sensor are perfect for clamping on existing electrical wiring by snapping around the current carrying cable. These are the best solution to measure or sense current passing through the center conductor, when the removal of cable lugs or termination is not feasible on critical installations.

Resources

Split-core Hall Effect Current Sensor are perfect for clamping on existing electrical wiring by snapping around the current carrying cable. These are the best solution to measure or sense current passing through the center conductor, when the removal of cable lugs or termination is not feasible on critical installations.

Resources

Open loop hall effect current sensor measure DC, AC and complex current wave forms with galvanic isolation. The advantages include low cost, small size, lightweight and low power consumption and are especially advantageous when measuring high currents.

Resources

Voltage transformers (VT), also called potential transformers (PT), are used for metering and are designed to present negligible load to the supply being measured . They have an accurate voltage ratio to enable accurate metering.

Resources

ELECTROHMS Split Core Current Transformer are designed for fast and easy installation without disconnecting cable or bus- bar circuits. These sensor's are compact in size and ideal for installation on existing cable.

Resources